CP Performance Boaters Shopping and Product Info Guide

1-800-225-9871

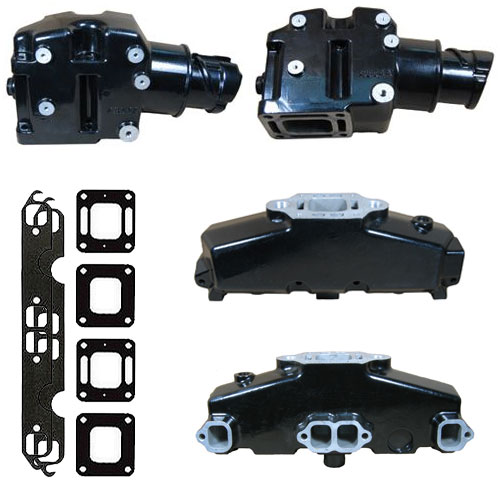

Hardin / HGE, Cast Aluminum / SS Riser Stock Mercruiser Replacement Exhaust Kits

Hardin Marine has teamed up with HGE exhaust to build afforable replacements for stock mercruiser cast iron exhaust systems. Available with Hardin Marine Stainless Steel tailpipes or standard cast aluminum risers, these kits are designed to replace Mercruiser #807078T10 and 89011A8 Manifolds, and #807988A03 and 44354A3 Risers in BBC applications.

Click on the part number to check pricing or place an order.

Hardin/HGE Exhaust

Systems

|

|||||||||||||||||

|

How are these manifolds built? HGE uses a “LPC” or “Low Pressure Casting”. LPC is a casting method that uses the pressure of inert gas to force the molten liquid metal from the bottom of the holding pot through a riser pipe into the tooling mold directly above. After the casting cools and solidifies, the pressure is reduced. The pressure applied usually does not exceed 1.0 bar, hence “low pressure casting”. The technology of “Lost Foam” casting is carried out by gravitational force (0.0689 bar, 1 atmosphere pressure) while LPC is done by pressurizing the molten liquid metal, usually at around 0.3 ~ 0.8 bar, 4.35~11.6 atmosphere pressure. LPC can be carefully controlled to eliminate porosity in the casting wall. This is because the molten metal becomes denser as it is squeezed into the mold by pressure, thus preventing gas bubbles and inclusions. The results are as superior as those produced by forging (manifolds can not be produced by forging). The LPC method allows for improved filling of thin-walled parts and large areas of tooling. These kits are available for Big Block and Small Block Chevy, and can be used as a direct replacement for old cast iron Mercury exhaust. Cast Aluminum Risers have built in mounting locations for you Mercury Brackets. The Stainless Steel Risers have brackets available for Mercury Components.

|

||||||||||||||||